Description

Elite Crete Systems E100 Series VR1

E100 VR1 Epoxy is a premium grade, 100% solids, true Self-levelling, ultra-clear epoxy floor coating resin suitable for creating metallic and Liquid Epoxy Marble flooring.

Advantages of E100- VR1

- The biggest advantages of VR1 Epoxy resin over other similar products are that it is a UV-resistant, true self-level product and it has an excellent ability to release bubbles, which makes it an excellent choice for metallic floor coating.

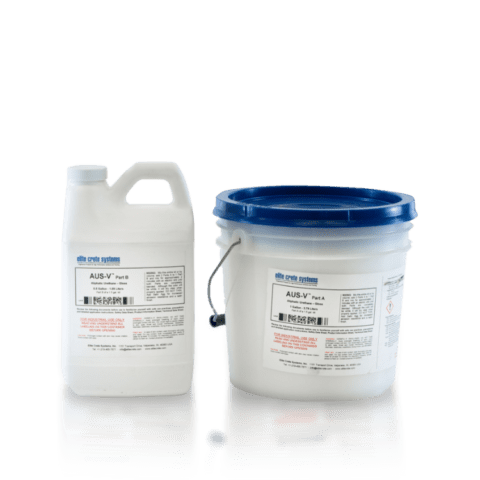

Not suitable for exterior surfaces as a top coat. for an external coating system consider using Elite Crete AUS-V - Excellent hot tyre pick-up resistance, which makes it a great choice for garage epoxy floors

- Excellent wear and abrasion resistance.

- Excellent fuel and chemical resistance.

- Produces smooth and glossy finish, slip resistance floor finishes can be achieved by adding anti-slip media to the coating system.

Areas of use

- Garage floors

- Showrooms

- Art Galleries

- Mancaves

- Whiskey and Cigar rooms

- Playrooms

- Inside homes

Elite Crete VR1’s Epoxy Packaging /Kit Size

Elite Crete VR1 is supplied in the following kit sizes

- 3 Gallons (11.4 litres)

- 15 Gallons (56 litres)

Recommended Preparation Method

Preparation is the key to achieving a long-lasting floor-coating system

Diamond grinding is recommended method of preparing new & old substrates prior to applying a decorative epoxy flooring Systems

The purpose behind concrete grinding is to remove any flaking paint and other types of contamination to achieve a clean surface as well as remove any sealer or curing agent and open concrete pores allowing the epoxy primer to penetrate deep into the surface and seal the floor.

Acid Etching might be used as an alternative option to prepare the floor for more information on how to acid etch your floor click here to be directed to an external blog. Hydrochloric acid can be purchased from pool shops or local hardware stores

Recommended diamond tooling grits to prepare the floor prior to applying Elite Crete’s epoxy system are

- 30/40 grit for hard concrete

- 80 Grit on soft concrete

- PCD plugs to remove flaking paint and then use grinding shoes to smooth out the floor before applying the coating.

- In between coats use 150-grit sanding discs to sand the floor prior to applying the metallic effect coat

Metallic Flooring

Typical Metallic flooring systems are made of a 3-step coating process and porous concrete substrates may require an additional primer coat

- Priming | recommended primer is Elite Crete E100-PT4 at a rate of 0.3 – 0.5 liter of product per sqm, which means a 3-gallon kit will be enough to prime 30-35sqm of floor area

- Metallic effect | VR1 and Metallic pigments are used to create this layer, recommended minimum application rate is 0.5 litres of product / per sqm, which means a 3-gallon Kit will cover up to 20 sqm of floor area

- minimum of 1 and maximum of 2 metallic pigment jars are recommended to be added to a 3-gallon Kit

- Top Coat| Elite Crete AUS-V high build water-based clear is recommended as the protective layer, this product is available in 1.5-gallon and 3-gallon Kit sizes, 1.5 gallon will cover up to 30sqm o floor area

Reflective Flooring and Catalogues

| Reflective System TDS | Reflector System Specs |

Flake flooring

Elite Crete’s VR1 Epoxy is an excellent choice for sealing over flake floors, the consumption rate is 0.3 litres per sqm and a 3-gallon kit will be enough to apply 1 generous coat to up to 35sqm of floor area

Hermatic Flake Flooring Information and Catalogues

| Hermatic System TDS | Hermatic Flake Floors |

Do not add thinners or methylated spirits to Elite Crete Systems.

Document Download

Click on the tiles below to download Elite Crete E100 Series VR1 Technical Data Sheets and Safety Data Sheets.

Additional Documents

| Residential Catalogue | Commercial Catalogue | Industrial Catalogue | Decorative Catalogue |

Reviews

There are no reviews yet.