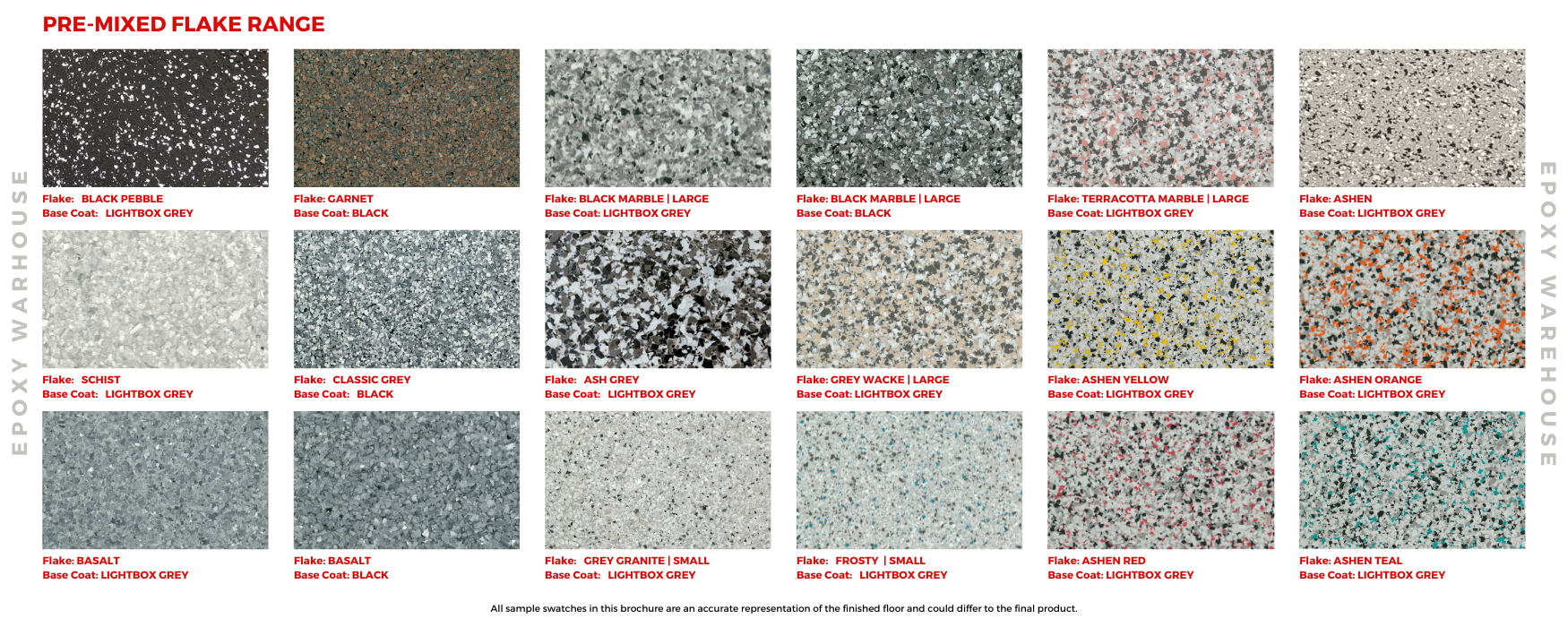

Flake Epoxy Flooring Systems

SEAMLESS FLAKE FLOORING RANGE

Flake Epoxy Flooring is a fantastic way to bring new life to your floor! With the correct preparation, and using premium grade floor coating products, you can achieve a professional floor covering that will last for many years to come. Epoxy Flake Floorings bring peace of mind as they are easy to maintain, extremely hard wearing and are designed to hide imperfections better than any other epoxy floor coating system.

Benefits of a Flake Epoxy Flooring System:

– Decorative & inviting

– Durable and long-lasting

– Can be applied Indoor and Outdoors

– Scratch and wear resistance

– Easy to clean and maintain

– Safe to Walk on

– Does not harbour bacteria

– Superior Chemical Resistance

– Permanent dust proofing solution

Our tailor made packages and products are available to suit your project needs. For further information on preparation, application and colours available, scroll down below.

Showing all 8 results

Steps to achieve a successfull Seamless Flake System

- Prepare the substrate thoroughly by diamond grinding or acid etching

To achieve a successful floor coating system make sure your surface is free of dust, oil/grease, any loose particles or paint and moisture. If your floor is subject to rising dampness, you would need to apply a moisture barrier primer prior to applying your base coat | more info - Repair cracks and imperfections using two-pack epoxy fillers

Fill in all your cracks using a 2-pack epoxy filler, such as Sikadur 31 CFN. For larger cracks and spalls, use Sydney Industrial Coatings’ Epoxy Coving and Repair Kit. The patching mortar will need to be fully cured before it can be grinded or coated and this process usually takes a minimum of 6 – 8 hours. - Apply epoxy primer to the floor and allow the coating to cure

General curing time (at 20°C) is a minimum of 8 hours. This can vary further if solvent has been added to the epoxy. - Return within 24 hours of applying the primer to remove rubbish and imperfections (by grinding down high sections and patching any low sections)

This is an important step for if the coating is left uneven, this will show though your final coat. If this step if not completed within 30 – 36 hours (depending on temperature) of applying the previous coat, the floor will need to be scratched using an 80 grit sand paper. - Apply an even coat of epoxy base coat and broadcast flake over the epoxy while the product is still wet and let it cure

Wearing spike shoes is required to walk over the epoxy and broadcast the flake evenly however you must apply safety practices and be cautious of injury. - Return the next day to vacuum/blow any loose flake and apply two clear top coats to achieve optimum results when sealing the flakes

General curing time (at 20°C) is minimum 8 hours for each coat of clear. Depending on the top coat being used, ensure correct amount of product is applied to the floor | If the floor is subject to heavy solvent, fuel or chemical spillage consider applying a two-pack clear top coat instead of a single pack. - Anti-slip media can be added to the topcoat to achieve a higher slip rating

As you will be applying a clear coat, ensure the aluminium oxide is not a noticeable colour. - On a freshly applied coating, the floor will be trafficable after a minimum of 24 hours and the recommended curing time before parking cars, boats, trailers or any other heavy objects, is a minimum 5 days after application of the final coat

FREQUENTLY ASKED QUESTION

What are the different epoxy flooring types?

Epoxy flooring comes in various types, including self-levelling epoxy, which creates a smooth and seamless surface; epoxy mortar systems, ideal for heavy-duty industrial settings; and decorative epoxy, incorporating colours and patterns for aesthetic appeal. We offer a few different styles in our range of epoxy systems, including:

- Solid colour

- Flake epoxy

- Metalic

How do I maintain epoxy flooring?

Maintaining epoxy flooring requires several key practices, including regular mopping with a mild detergent, cleaning up spills to prevent stains, reapplying a topcoat every few years and avoiding hard chemicals and cleaners in general.

How much epoxy flooring cost?

The cost for epoxy flooring systems will vary, depending on the system you choose. Please have a look at our individual epoxy flooring systems or enquire for pricing.

Click here to view our Flake Epoxy Flooring PDF Brochure